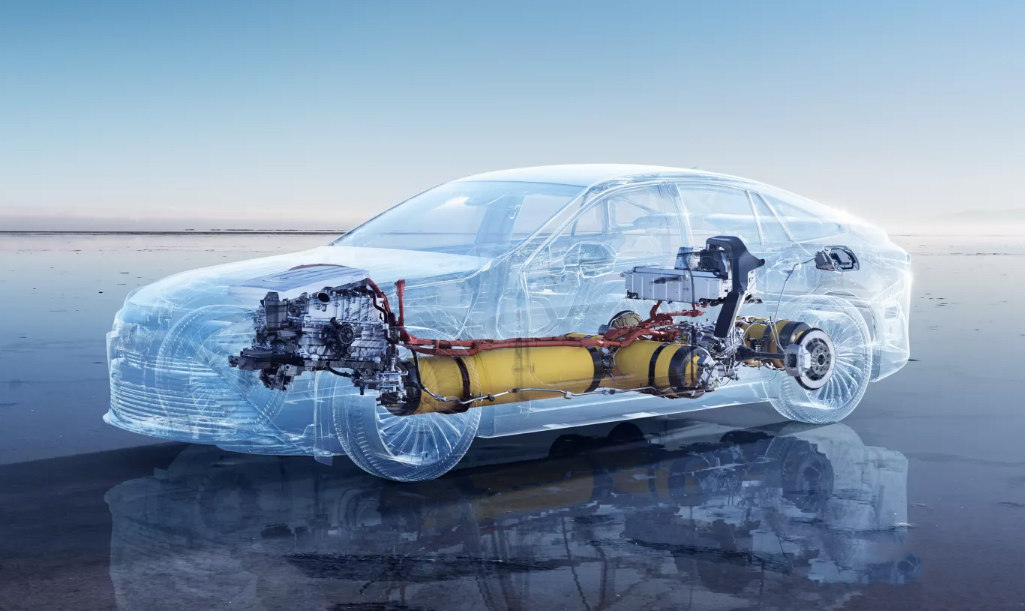

Ngokuphikisana nokuguquka kwamandla omhlaba wonke okusheshayo, amaseli kaphethiloli we-hydrogen, njengomthwali obalulekile wamandla ahlanzekile, aletha amathuba okuthuthukiswa angakaze abonwe. I-membrane electrode assembly (MEA), njengengxenye eyinhloko yeseli kaphethiloli, ithinta ngqo ukusebenza kahle kanye nokuphila kwesikhathi sohlelo lonke lweseli. Phakathi kwalokhu, inqubo yokulungiselela iphepha lekhabhoni le-gas diffusion layer (GDL), ikakhulukazi inqubo yokwelapha nokubumba, inquma ngqo isakhiwo se-porosity, i-conductivity, kanye namandla okusebenza e-GDL.

Amaphuzu Amane Obuhlungu Obuyinhloko kanye Nezixazululo Ekukhiqizweni Kwephepha Lekhabhoni le-GDL

Kubakhiqizi bephepha lekhabhoni le-GDL lamaseli kaphethiloli e-hydrogen, isihluthulelo sokuwina imakethe sisekutheni bangakwazi yini ukukhiqiza iphepha lekhabhoni elisebenza kahle kakhulu ngendlela ezinzile, ephumelelayo, nengabizi kakhulu. Imishini yokukhiqiza yendabuko (njengemishini yokucindezela eyisicaba kanye nemishini yokucindezela egoqekayo) ibeka izithiyo eziningi endleleni eya ekukhiqizweni okukhulu.

Iphuzu Lobuhlungu 1: Ukungaguquguquki komkhiqizo, izinga eliphansi lokukhiqiza, kanye nobunzima bokulethwa ngobuningi

Inkinga Yendabuko: Ukucindezela okuyisicaba kwendabuko kuthinteka ukunemba kokucubungula kwamapuleti okucindezela ashisayo kanye nokuguquguquka kokushisa kwamapuleti ngemva kokushisa, okuholela ekuphambukeni okuphezulu ekufaneni kobukhulu bephepha lekhabhoni elilungisiwe. Ngaphezu kwalokho, indlela yokucindezela ngezikhathi ezithile ivumela kuphela ukukhiqizwa kwamaphepha obukhulu obuthile, okwenza kube nzima ukunikeza amakhasimende imiqulu yobukhulu obuhlukahlukene. Ukucindezela okuyisicaba kwendabuko kusebenzisa ingcindezi ngokuxhumana komugqa, kanti ingcindezi yehla kusukela maphakathi nama-rollers iye emaphethelweni, okwenza iphepha lekhabhoni libe qinile phakathi futhi likhululeke emaphethelweni. Lokhu kuholela ngqo ekujikeni okungalingani kanye nokusatshalaliswa kwemigodi engaguquki. Ngisho nangaphakathi kweqoqo elifanayo, noma ngisho nephepha lekhabhoni elifanayo, ukusebenza kungashintshashintsha, lapho isivuno sizungeza cishe ku-85% esikhathini eside, okubeka ingozi enkulu yokulethwa kwe-oda elikhulu.

Isixazululo sengcindezi ye-Mingke isostatic: Ubuchwepheshe be-isostatic bufinyelela ingcindezi efanayo 'yokuxhumana kwendawo' yangempela ngokusekelwe emthethweni kaPascal we-fluid mechanics. Njengengcindezi ye-hydrostatic olwandle olujulile, isebenza ngokufanayo kuzo zonke izindawo zephepha lekhabhoni kuzo zonke izinkomba.

ImiphumelaUmphumela:

- Ukujiya Ukungaguquguquki:Qinisa ukubekezelelana kobukhulu kusukela kuma-micron ayishumi nambili kuya ngaphakathi±3μm.

- Ukufana Kwezimbobo: Izimbobo zingagcinwa njalo ngezinga eliphezulu lika-70% ±2%.

- Ukuthuthukiswa Kwesivuno: Izinga lesivuno likhuphuke lisuka ku-85% laya ngaphezu kuka-99%, okwenza kube nokulethwa okuzinzile, okukhulu, nekhwalithi ephezulu.

Iphuzu Lobuhlungu 2: Ukusebenza kahle kokukhiqiza okuphansi, izithiyo ezivelele zamandla, kanye nezindleko eziphakeme

Inkinga Yendabuko: Izinqubo eziningi ze-lamination ezisezingeni eliphezulu 'zisekelwe ku-batch,' njengehhavini lasekhaya, zibhaka i-batch eyodwa ngesikhathi. Ijubane lokukhiqiza lihamba kancane, imishini ivulwa futhi ivalwe njalo, ukusetshenziswa kwamandla kuphezulu, ukuncika kwabasebenzi kunamandla, futhi umkhawulo wamandla useduze.

Isixazululo se-Mingke Isostatic: Umshini wokucindezela we-isostatic onebhande eliphindwe kabili uklanyelwe ngokuyinhloko njengomhubhe osebenza njalo 'wokushisa okuphezulu, onomfutho ophezulu.' I-substrate ingena isuka kolunye uhlangothi, idlula enkambisweni ephelele yokuminyana, ukupholisa, kanye nokuqeda, futhi iphuma njalo isuka kolunye uhlangothi.

Imiphumela Yesixazululo:

- Ukwanda Kokukhiqiza: Kuvumela ukukhiqiza okuqhubekayo kwamahora angama-24, ngesivinini esifinyelela kumamitha angu-0.5-2.5 ngomzuzu, kanye nomkhiqizo waminyaka yonke ofinyelela kumamitha-skwele ayisigidi ngomugqa wokukhiqiza, okwandisa ukusebenza kahle ngokuphindwe kahlanu.

- IzindlekoUkuxuba: Umphumela wesilinganiso sokukhiqiza oqhubekayo wehlisa kakhulu ukwehla kwenani, amandla, kanye nezindleko zabasebenzi ngemitha yesikwele.Izilinganiso zineumbukisonukuthi izindleko zokukhiqiza zizonke zingancishiswa ngo-30%.

- Ukonga Abasebenzi: Izinga eliphezulu lokuzenzakalela livumela ukwehla okungu-67% kwabasebenzi ngokushintshwa ngakunye.

Iphuzu Lobuhlungu 3: Iwindi lenqubo encane, izindleko eziphezulu zokulungisa amaphutha nokuzama, kanye nokusungula izinto ezintsha okulinganiselwe

Inkinga Yendabuko: Ukusebenza kwephepha lekhabhoni le-GDL kuzwela kakhulu ekushiseni nasekucindezelweni. Imishini yendabuko ayikwazi ukulawula izinga lokushisa ngokunembile futhi inomgoqo owodwa wokucindezela, okwenza kube nzima ukuphinda ngokunembile inqubo efanele yelabhorethri. Ufuna ukuzama ifomula entsha noma isakhiwo esisha? Umjikelezo wokulungisa amaphutha mude, izinga lokukhubazeka liphezulu, futhi izindleko zokuzama nokwenza amaphutha ziyashaqisa.

Isixazululo se-Mingke static pressure: Sihlinzeka ngeplatifomu yenqubo eguquguqukayo kakhulu futhi elawuleka kahle.

Imiphumela Yesixazululo:

- Ukulawula Izinga Lokushisa Elinembile: Ukulawula izinga lokushisa okuzimele kwezindawo eziningi ngokunemba okufika ku-±0.5℃, okuqinisekisa ukuphiliswa kwe-resin okuphelele.

- Ukucindezela Okulungisekayo: Ukucindezela kungabekwa futhi kugcinwe ngokunembile ngaphakathi kobubanzi bebha engu-0-12 ukuze kufane ngokuphelele.

- InquboUkukhishwa: Uma sekutholakale amapharamitha afanele, “angakhiywa” ngokuchofoza okukodwa ohlelweni, kufezwe ukuphindaphindwa kwenqubo okungu-100% futhi kuqinisekiswe ukusebenza komkhiqizo okuzinzile.

- Ukuthuthukisa i-R&D: UNanjing Mingke okwamanje unezinhlelo ezimbilii-ouble-imishini yokuhlola ukucindezela okungabonakali kwebhande, enikeza ipulatifomu yokuhlola ethembekile, esezingeni lokukhiqiza yocwaningo nokuthuthukiswa kwezinto ezintsha nezakhiwo ezintsha, kunciphisa kakhulu izithiyo nezingozi zokusungula izinto ezintsha. Ngesikhathi esifanayo, kwamabhizinisi amasha anemali encane yokuqala kanye nobunzima bokuthenga imishini, izinsizakalo zokukhiqiza izinkontileka ezincane ezisukela esontweni elilodwa kuya enyangeni eyodwa zinganikezwa ukuthuthukisa amakhono okulethwa kwemikhiqizo yephepha lekhabhoni, ukusiza amabhizinisi ukuthi aqhube ukukhiqizwa kokuqala kokuhlola, ukunciphisa ukutshalwa kwezimali okukhulu kwemishini kusengaphambili, kanyenciphisaizingozi.

Iphuzu Lobuhlungu 4:I-Phenolic resin ephilisa i-glue residue egcwele, ukulahleka okukhulu kwephepha lokukhulula noma izinto ezisizayo ze-ejenti yokukhululas.

Inkinga Yendabuko: Ngemva kokwelashwa kwe-phenolic resin, kunzima ukuhlukanisa nepuleti lokunyathelisa noma ibhande lensimbi. Izinkampani zendabuko ngokuvamile zisebenzisa ama-release agents noma iphepha lokukhulula ukuze kufezwe inqubo yokususa, kodwa ama-release agents asezingeni eliphezulu noma amaphepha okukhulula ayabiza ukuwathenga, futhi ukusetshenziswa okuphezulu ngesikhathi senqubo yokukhiqiza kwandisa izindleko zokukhiqizwa kwephepha lekhabhoni, okungavumeli intengo yomkhiqizo encintisanayo emakethe.

Isixazululo se-Mingke Isostatic: Umshini wokucindezela we-isostatic webhande lensimbi eliphindwe kabili likaMingke uvumela amakhasimende ukuthi akhethe amabhande ensimbi okucindezela afakwe i-chrome.

Umphumela Wesixazululo: Ngokuhlolwa kwangaphakathi okwenziwe eMingke Factory kusetshenziswa amabhande ensimbi afakwe i-chrome ephepheni lekhabhoni elicwebezelayo, kwatholakala ukuthi uma kuqhathaniswa namabhande ensimbi acindezelwe endabuko, amabhande ensimbi afakwe i-chrome ahlinzeka ngokusebenza okungcono kokupholisa nokukhulula i-resin. Izinsalela zeglue ezengeziwe kulula ukuzisusa, futhi uma zisetshenziswa ngebhulashi lokuhlanza elihambayo, iglue esele ebusweni bebhande lensimbi ingasuswa kalula, okusiza amakhasimende ukunciphisa izindleko kuma-release agents kanye nephepha lokukhulula. Ingqimba ye-chrome ebusweni bebhande lensimbi ithuthukisa kakhulu ubulukhuni kanye nokumelana nokuguguleka kwebhande. Ngaphezu kwalokho, ifilimu ye-oxide ecijile eyakhiwe ungqimba lwe-chrome ebusweni bebhande lensimbi ivimbela ngempumelelo ukuguguleka komoya-mpilo, amanzi, nezinye izinto ezibolayo, ngaleyo ndlela yandisa impilo yenkonzo yebhande lensimbi.

Kubasebenzisi asebethembele emishinini engenisiwe isikhathi eside, iNanjing Mingke, njengenkampani yasekhaya, inikeza ikhambi elingcono:

- Ukushintshaniswa kwempahla yasekhaya: Yephula ubunikazi bokungenisa impahla, kube nezinzuzo ezindleleni zokuthenga nokulungisa imishini.

- Impendulo esheshayo yesevisi: ukwesekwa kobuchwepheshe amahora angama-24, onjiniyela abakhona endaweni zingakapheli amahora angama-48, bebhekana ngokuphelele nempendulo ehamba kancane ngemva kokuthengisa kanye nemijikelezo emide yezingxenye zemishini engenisiwe.

Imiphumela yangempela yohlelo lokusebenza: ukudala inani elibalulekile kumakhasimende

Ngemva kokuba inkampani eyaziwayo yamaseli kaphethiloli e-hydrogen yamukele umshini wokunyathelisa webhande lensimbi eliphindwe kabili i-Minke isostatic, yathola imiphumela emangalisayo ekukhiqizweni kwephepha lekhabhoni le-GDL.

- Ukuthuthuka okuphawulekayo ekuvuneni komkhiqizo: kukhuphuke kusuka ku-85% ezinqubweni zendabuko kuya ngaphezu kuka-99%.

- Ukuthuthukiswa okuphawulekayo ekusebenzeni kahle kokukhiqiza: umthamo wokukhipha nsuku zonke ufinyelela kumamitha-skwele angu-3,000.

- Ukusetshenziswa kwamandla okuncishisiwe: ukusetshenziswa kwamandla sekukonke kwehle ngo-35%.

Ukuthuthukiswa Kokusebenza Komkhiqizo:

- Ukufana kwe-Porosity: 70% ± 2%

- Ukumelana nendiza: < 5 mΩ·cm

- Ukumelana nendiza edlulayo: < 8 mΩ·cm²

- Amandla Okudonsa: > 20 MPa- Ukujiya Ukufana: ±3 μm

Kuqediweuhlelo lwesevisi kanye nosekelo lobuchwepheshe

Nanjing MingkeInquboI-Systems Co., Ltd. inikeza amakhasimende ukwesekwa okuphelele kwesevisi yobuchwepheshe:

1. Ukusekelwa Kokuthuthukiswa Kwezinqubo

AIthimba lobuchwepheshe lochwepheshe lisiza amakhasimende ekwenzeni ngcono imingcele yenqubo nokulungisa imishini, ukuqinisekisa ukuthi imishini ihlangabezana nezidingo ezithile zenqubo yokukhiqiza.

2. Izinsizakalo Zemishini Eyenziwe Ngokwezifiso

Nikeza izinsizakalo zemishini ezenziwe ngokwezifiso ngokuya ngezidingo ezikhethekile zamakhasimende, kufaka phakathi osayizi abakhethekile, ukucushwa okukhethekile, njll.

3. Izinsizakalo Zokufaka Nokugunyaza

Ithimba lobunjiniyela elinolwazi lihlinzeka ngezinsizakalo zokufaka kanye nokufaka imishini endaweni ukuqinisekisa ukuthi imishini ingafakwa ngokushesha ekukhiqizweni.

4. Ukuqeqeshwa Kobuchwepheshe

Nikeza ukuqeqeshwa okuphelele kokusebenza nokugcinwa ukuqinisekisa ukuthi amakhasimende angakwazi ukusebenzisa nokunakekela imishini kahle.

5. Usekelo Lwangemva Kokuthengisa

Misa indlela yokuphendula ngokushesha amahora angama-24 ukuze unikeze isevisi yangemva kokuthengisa kanye nokusekelwa kobuchwepheshe ngesikhathi esifanele, uqinisekise ukukhiqizwa okungaphazamiseki.

Imboni inamathemba amaningi okusebenzisa.

Umshini wokucindezela webhande lensimbi eliphindwe kabili le-Mingke awufaneleki nje kuphela ekukhiqizweni kwamaphepha e-carbon e-GDL amaseli kaphethiloli we-hydrogen, kodwa futhi ungasetshenziswa kabanzi emikhakheni eminingi:

- Amaseli kaphethiloli: Iphepha lekhabhoni le-GDL, ukulungiswa kwesendlalelo se-catalyst;

- Amabhethri e-Solid-state: ukuhlanganiswa kweshidi le-electrode kanye ne-molded;

- Izinto ezihlanganisiwe: ukulungiselela kusengaphambili i-carbon fiber;

- Iphepha elikhethekile: ukuqina okuphezulu kanye nokubumba;

- Izinto ezintsha zamandla: ukulungiswa kwezinto ezahlukahlukene ezisebenzayo zefilimu encane.

Izinzuzo ze-Mingke Double Steel Belt Isostatic Press:

I-Nanjing Mingke ichithe iminyaka eyishumi ilola ubuchwepheshe bayo futhi iqhubeka nokutshala imali ocwaningweni nasekuthuthukisweni kwemishini yokucindezela ephindwe kabili yebhande lensimbi. Manje sebenemishini yokucindezela eshisa kakhulu efinyelela ku-400°C ngokunemba kwengcindezi okulawulwa ngaphakathi kuka-±2%. Ngenxa yalobu buchwepheshe, i-Mingke iyisinqumo esingcono kakhulu semishini yokucindezela yokwelapha iphepha le-carbon uma ucabangela inani lemali kanye nengozi encane. Namuhla, izinkampani eziningi zasekhaya zokuhlanza iphepha le-carbon roll-to-roll zikhetha i-Nanjing Mingke njengomlingani wazo.

Isikhathi sokuthunyelwe: Okthoba-09-2025